PRODUCTS

Resist Processing

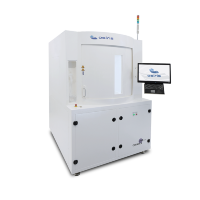

Automatic production systems

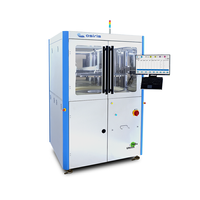

VARIXX-SERIES

- Flexible configuration of processing modules

- Available modules: spin coater, spray coater, developer, temperature and smart-EBR

- Handling thin, standard or bonded wafer (Si, glass & others)

- Round wafer up to Ø300 mm (Ø12 inch)

- Square substrates size up to 230 x 230 mm (9 x 9 inch)

Optional sub-systems; wafer flipper, PR dispense system (pumps, syringe, CPD) and media supply cabinets with various canister designs.

Designed to be used in applications:

SPIN (SPRAY) COATING, DEVELOPING, BAKING & COOLING AND EBR

VARIXX 804

(Ø200mm) with 4 process modules

VARIXX 806

(Ø200mm) with 6 process modules

VARIXX 1204

(Ø300mm) with 4 process modules

Semi-automatic production systems

UNIXX-SERIES

- Spin & spray coater, developer, temperature and smartEBR modules are available as stand-alone, table-top or bench mounted configurations.

- Base frame design allows various process modules configurations.

- Round wafer up to Ø300 mm (Ø12 inch)

- Square substrate size up to 230 x 230 mm (9 x 9 inch)

Our product range also offers customized single processing systems for large substrates up to 1.300 x 1.300 mm (51 x 51 inch).

Optional sub-systems; PR dispense systems (pumps, syringe or CPD).

SPIN COATER - CCP

Designed to be used in applications:

SPIN COATING with Covered Chuck Processor (CCP)

UNIXX S760+

(21x21 inch) Stand-alone system

spin coater for large substrates.

UNIXX SA30+

(Ø300mm) Stand-alone system with

covered chuck spin coater. (single base frame)

UNIXX SHp22+

(Ø200mm) Stand-alone system with

covered chuck spin coater & hotplate module.

SPIN COATER - open bowl

Designed to be used in applications:

SPIN COATING with open-bowl for standard coating.

UNIXX SA30

(Ø300mm) Stand-alone system with

open bowl spin coater. (single base frame)

UNIXX SHe22

(Ø200mm) Stand-alone system with

open bowl spin coater & hotplate module.

DEVELOPER

Designed to be used in applications:

DEVELOPING, CLEANING AND DRYING

UNIXX D20 Advanced

(Ø200mm) Stand-alone system with movable splash ring for manual load-/unload of single substrates.

UNIXX D30 Standard

(Ø300mm) Stand-alone system provide users

in science, and research with a productive, safe and clean system.

EBR

Designed to be used in applications:

smartEBR to clean the edge on flat or notch wafers.

UNIXX EBR A20

(200x200mm) Stand-alone smartEBR system.(single base frame)

HOTPLATES

Designed to be used in applications:

SOFTBAKE (PRE-BAKE), HARDBAKE,

OPTIONAL FOR HMDS (HEXAMETHYLDISILAZANE): VAPOR PRIMING, VACUUM DRYING

UNIXX H1403

(40x40 inch) Stand-alone hotplate system with 3 hotplate modules up to 1.000 x 1.000mm substrates.

UNIXX H760

(21x21 inch) Stand-alone hotplate system up to 537 x 537mm or customized rectangular substrates.

UNIXX He45

(Ø450mm) Stand-alone hotplate system for round or up to 320 x 320mm square

substrates.

UNIXX HvT20

(Ø200mm) Table-top hotplate tool for HMDS priming and vacuum dehydration bake.

(available bench mounted or stand-alone)

UNIXX HeT20

(Ø200mm) Table-top hotplate tool with electronic driven lifting pins.

(or bench mounted)

UNIXX HpT20

(Ø200mm) Table-top hotplate tool with pneumatic driven lifting pins.

(or bench mounted)

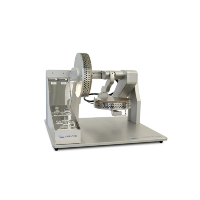

SPRAY COATER

Designed to be used in applications:

SPRAY COATING for all topographies and shapes.

3D & 2D SPRAY COATER SYSTEM for flat, concave or convex surfaces

- For large scale optical devices and substrates up to 21‟x 21‟

- 6 axis robot system & up to 2 ultra-sonic spray nozzles

- Integrated heating chuck under the spray coating area

SPRAY COATER MODULE for surfaces with topographic structure

- Wafer size up to Ø 300 mm (Ø12‟)

- Module can be installed in automatic systems

Optional sub-systems; PR dispense systems (pumps and syringe).

UNIXX SP 760

(21x21 inch) Spray coater system with integrated heating chuck for large substrates.

UNIXX SP H22

(Ø200mm) Spray coater system with hotplate module.

UNIXX SP B20

(Ø200mm)

Bench mounted spray coater module.

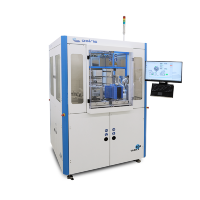

WET PROCESSING

Semi- or fully-automatic production systems

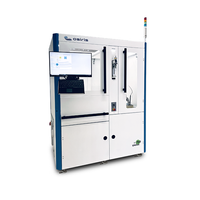

CHEMIXX-SERIES

MECHANICAL PROCESSING

- High pressure nozzle

- Megasonic or ultra-sonic nozzle

- Large area megasonic

- Single or double-sided brush

CHEMICAL PROCESSING

- SPM, SC1, SC2, DHF

- BHF, SiO2, Metal etch

- Chemicals via puddle or spray nozzle

Pre-defined systems for standard processes such as mask cleaning,

metal lift-off, post CMP clean and scrubbers or customized tools.

Designed to be used in applications:

WET CLEANING, ETCHING, POST CMP CLEAN AND METAL LIFT-OFF

CHEMIXX CL30

(Ø300mm) Wet cleaning system with

DI-Chamber rinse (optional).

CHEMIXX CMP30

(Ø300mm) Wet cleaning system for cleaning of dry and wet wafers after CMP.

CHEMIXX E 30 MASK

(9x9 inch) Photomask cleaning system.

CHEMIXX 760

(21x21 inch) Single processing cleaning, etching or developing system with integrated media supply for large substrates.

CHEMIXX 1201

(Ø300mm) Automatic cleaning, etching or developing processing system with one process chamber.

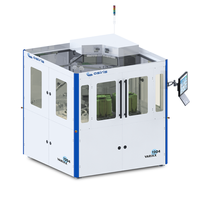

TEMPORARY BONDING

Manual to automatic production systems

AFIXX-SERIES

- Wafer sizes from pieces up to Ø200 mm (Ø8 inch)

- Suitable for very thin fragile wafers (< 40 μm) and flexible plastic materials.

- Compatible with silicon, compound and glass materials

- Uniform and repeatable mounting process is ideal for CMP, grinding, polishing and etching.

Temporary bonding material mroBOND L1.1.DS are organic coatings that enable back-end-of-line (BEOL) processing of ultra-thin wafers using standard semiconductor equipment.

MOUNTING ONTO DIFFERENT TYPES OF CARRIER SUBSTRATES: GLASS, SAPPHIRE, SILICON OR CERAMIC.

Designed to be used in applications:

TEMPORARY BONDING

AFIXX 22a

(Ø200mm) Automatic system with

hotplate & I/O stations.

AFIXX 20s

(Ø200mm) Semi-automatic system

with 200ºC hotplate.

AFIXX 20m

(Ø200mm) Manual system with 200ºC hotplate.

DEBONDING

Manual to automatic production systems

DEFIXX-SERIES

- Wafer sizes from pieces up to Ø300 mm (Ø12 inch)

- Imbedded heaters on wafer and carrier plates

- Compatible with silicon, compound and glass materials

- Usable with a wide range of debonding materials

It is a versatile tool that is ideal for many R&D wafer debonding applications and low volume production.

DEMOUNTING OF BACKSIDE GROUND, THINNED AND POLISHED WAFERS.

Designed to be used in applications:

DEBONDING

DEFIXX 20a

(Ø200mm) Automatic system with robot loading and unloading. (cassette to cassette)

DEFIXX 20s

(Ø200mm) Semi-automatic system with manual loading and unloading station.

DEFIXX 30m

(Ø300mm) Manual system with imbedded heaters on wafer and carrier plates.

SUB-SYSTEMS

In addition to our processing systems Osiris International also offers sub-systems (e.g. dispensing systems, media supply cabinets with various canister designs).

Dispensing systems

OOPXX

Oyster dispensing pump

(max. dispense volume 180ml)

For high material viscosity:

Photoresist positive & negative, bonding material or solvent.

- Programmable pressure, rate and speed

- Incl. suck-back valve

PD-10

Pneumatic diaphragm pump system

Handles a wide range of media viscosities, from solvents up to photoresist.

FOR APPLICATIONS

- Photoresist coating for SEMI applications

- Edge cleaning with solvents

- Protective coating

Syringe

Automatic syringe dispense system

Dispensing of small media amounts or continuous dispense for μl/sec or any ml/sec

- Syringe made of glass or one-way syringe of plastic

- Different syringe sizes available: 10ml, 20ml, 50ml, 100ml and 200ml

- Programmable suck-back volume and rate

Media supply cabinets

Active media cabinet

Storage up to three acid-canister

PE-HD 10 ltr. tank

Various media canister designs

- Canister sizes: 5, 10, 20 ltr.

- Canister Materials: SS, PP, HDPE, PVDF

- Media can be heated or temperature stabilized

- Continuous Pump with ultrasonic flow sensor or pressurized tank with manual flow mtr.

dw.jpg/picture-200?_=18b90936109)